Affordable Animal Incinerators for Farms and Veterinary Hospitals In the evolving landscape of animal waste management, […]

Petrol: diesel Consumption: 8-10liter/hour Capacity: to cremate (carrion and spoils) 350-400kg/hour Temperature: 900-1350?C […]

Waste Incineration in Papua New Guinea: A Step Towards Sustainable Waste Management In the heart of […]

j) Controls i) The controls (i.e., switches, knobs, etc.) should be visible and clearly identified, and […]

Basic Info. Pullution Sources:Solid Waste Processing Processing Methods:Combustion Export Markets:Global Additional Info. Trademark:Clover Incinerator Product Description […]

Transforming Waste into Energy: The Role of HiClover’s Mobile Waste-to-Energy Incinerator The Energy Crisis and Waste […]

CONTAINERIZED BURNER FOR INCINERATING HAZARDOUS AND NON HAZARDOUS WASTES (BOTH DOMESTIC As Well As INDUSTRIAL) AT […]

Incinerator for Biomedical Waste: A Vital Solution for Safe and Effective Disposal Biomedical waste, also known […]

Basic Info. Model NO.:crematorium equipment prices Export Markets:Global Product Description Nanjing Clover Medical Technology Co., Ltd. […]

Coronavirus Disease 2019 (COVID-19) pandemic continues all over the world, clinics,hospitals,goverment may need to consider on-site […]

Basic Info. Model NO.:incineration unit for hospital waste Export Markets:Global Product Description Key Features: * All […]

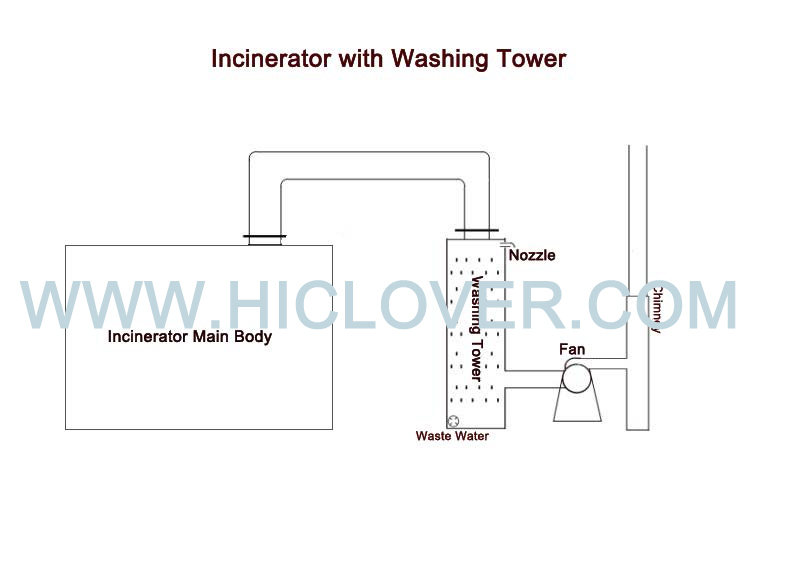

1.A chamber of post combustion of gasesA burner of combustion of gases,A device of injection of air allowing a total re-combustion of gases,A device of air inlet of cooling of waste gases,A sheath of evacuation of the gases burnt,Carcass in strong sheet steel with support of connectionComposition of the refractory;Refractory concrete:Thickness :>150mmNature: 65%% of Al203Insulate in fibrous panels:Thickness: >85mmNature: CalciumBurner with fuel, mono-bloc casting guiding type with horizontal flame, lighting and safety of electronic ignition, permanent ventilation, electromagnetic sluice gate of regulation and isolating valve.A secondary injection of air to ensure perfect oxygen content.2.A control box ensuring the complete cycle of combustion.3.Fan:Electro-ventilator distributing the secondary air, the regulation of the air flow being carried out by valves and following the control of the automatic cycle.4.Controls and regulations:Control box watertight to dust, including:A switch circuit breaker for each engine (ventilators and burners).A timer with adjustable temporization for the regulation of each burner.A regulator with digital watching for the temperature of combustion.A regulator with digital watching for the temperature of post-combustion.Electric box.5.The de-ashing must be done in the bottom of the combustion chamber or the de-ashing should be automatic or manual batch de-ashing.6.Process filtering system: scrubber to be mentioned as optional7.Emission standards compliance: BS 3316 or equivalent standard8.Capacity to treat plastic: not less than 40% by weight9.CE manufacturing compliance: BS EN 746-2-1997

RECYCLABLE WASTE PLASTIC (NON-PVC) 218,693 CARDBOARD 85,046 PAPER 4,956 PVC 15,115 CONTAMINATED MATERIALS MEDICAL WASTE 1,084 […]

Primary chamber – Consists of a monolithic high grade refractory concrete with high grade insulation backing, […]